|

|

|

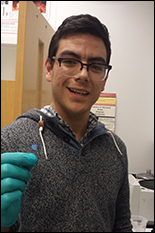

Picture 1: Torres holds a thin film of milky plastic that can be used to detect trillionth parts of a solution of enzymes with a dramatic color change.

Picture 2: Three projects of the FML in 2017: nanoparticle polymer film to detect enzymes, sprayable plastic bandage, and polymer-filled battery. |

|

The Functional Macromolecular Laboratory (FML), just a small sliver of space in the Clark School's Jeong H Kim Building, looks like other labs with its black counters and chemical supplies crammed onto shelves. But its students, of professor Peter Kofinas, Professor in Bioengineering, and Associate Dean for Faculty Affairs and Graduate Programs, are extraordinary. And what sets them apart is their creativity, a feature that Kofinas "encourages, even insists on," says 3rd Year PhD student Leo Torres.

The laboratory has been in operation since 1996, and its purpose is to enhance conventional synthetic polymers with functionality, using their mechanical, thermal, and conductive properties at the micro scale for applications in electronics, sensing, and surgery.

Torres displays recent work with biomedical applications. Previous colleagues developed a way to improve and replace conventional sutures in intra-abdominal surgeries using specially-made polymer fibers that at body temperature, form a homogenous sticky film that adheres to human tissue. This work, in conjunction with Children’s National Hospital, uses an airbrush to deposit polymer fiber mats. Future work for this project is to incorporate reactive chemical groups to the surface of the sealant in order to improve the adhesive properties.

Torres' own work is being able to detect small quantities of enzymes, by fabricating materials that produce dramatic color changes based on the distance between sub-microparticles embedded in a polymer hydrogel. Even a miniscule amount, a microgram per milliter, can be detected with a discernable change from one color to another. Currently, he is testing his sensing platform on botulinum toxin, an extremely potent toxin, as a proof of concept. Previous students have also made similar sensors to detect sugars and proteins.

The FML is also tackling the issue of battery failure in implanted biomedical devices and commercial electronics, by creating safer batteries that use solid polymer electrolytes instead of conventional organic electrolytes, which are flammable. These solid polymer electrolytes function similarly to that of conventional batteries, but are much smaller in size. Safer batteries like these could be used to power pacemakers, cellphones, or other devices.

The sprayable polymers have electronic applications, too. Students in the FML sprayed conductive fiber composites onto a lab glove and fabricated flexible stretchable circuits. By touching their fingers in different patterns, different circuits could be activated and yield resistances that do not change with strain, allowing for stretchable and bendable devices.

"Every project here has an application, and some projects have spun out into companies," says Torres. "But the best aspect of the lab is that creativity is key."

June 13, 2017

|