|

|

|

The structure of natural materials is inspiring the development of innovative technology more and more often these days. For example, the ribbed design of Speedo’s FastSkin swimwear is inspired by the scales of shark skin. Lockheed Martin created a new rotor for their Samarai UAV motivated in part by the swirl of maple seeds. In the University of Maryland (UMD) Department of Chemical and Biomolecular Engineering (ChBE), researchers have drawn inspiration from layered materials found in nature – onions, castor beans, eggs and the discs in our spinal column, to name a few – to design multi-layered polymer capsules. Such capsules could serve numerous purposes, especially in the pharmaceutical industry as containers for delivering drugs.

In their research, ChBE Professor Srinivasa Raghavan and his PhD Student, Brady Zarket, have invented a technique where they begin with a small gelatinous bead and then grow layers of different polymers around this bead. Each layer is grown by immersing the core in a solution of monomers, which polymerize around the core in a minute or so. The process is repeated multiple times to form an onion-like capsule with multiple concentric layers, each of a unique chemical composition. Interestingly, each layer grows ‘inside-out’, i.e., the growth starts at the core and extends outward, with the thickness depending on the amount of molecules called ‘initiators’ that are present in the core.

According to Raghavan, “the beauty of this technique is that we can control the growth of each layer – so we can decide what the layer is made of and how thick it is. This is something that cannot be done by any existing method.”

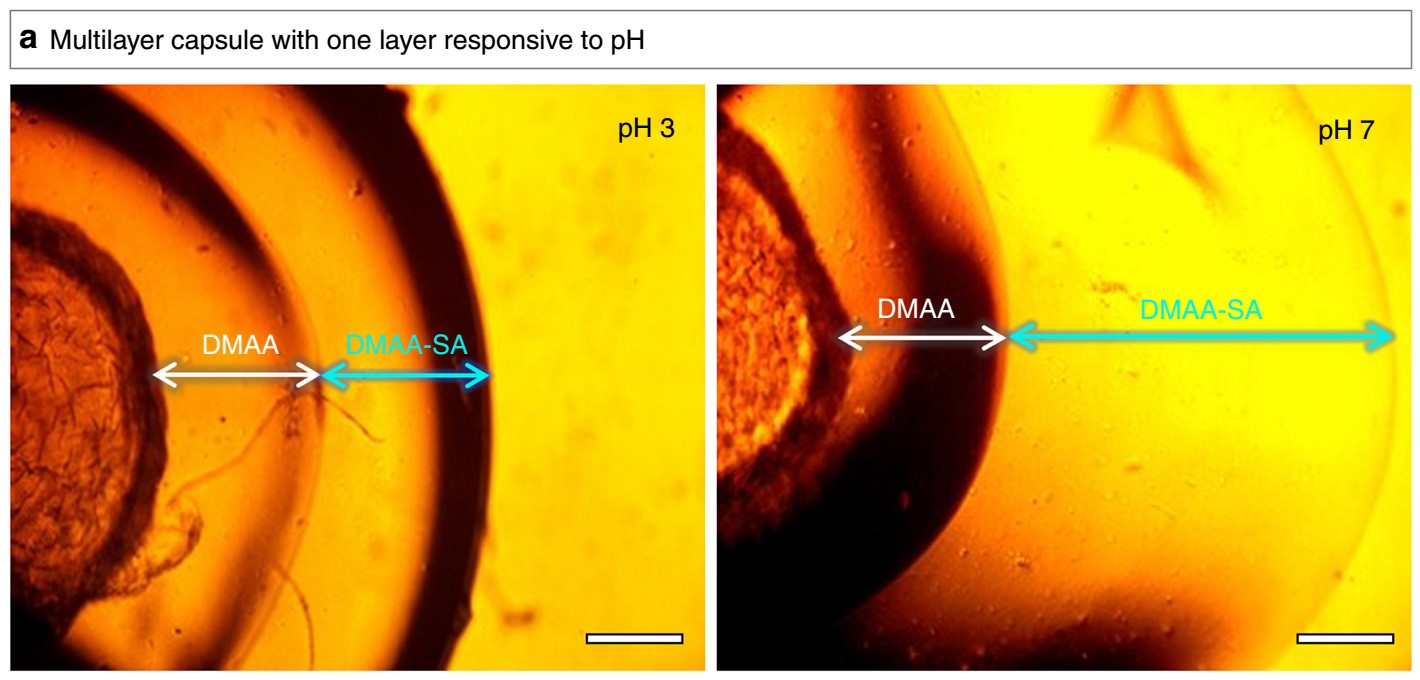

As an example of the technique’s versatility, the researchers created a capsule in which one of the layers is made from polysodium acrylate (SA), which is the polymer used in disposable diapers because of its ability to swell and thereby absorb water. The swelling of this polymer is known to be dependent on the pH of the surrounding water – it swells much more at normal pH rather than in acidic (low pH) water. Accordingly, the SA-bearing layer in their onion-like capsule exhibits a dramatic change in its thickness with a change in pH, as shown in the figure above.

The overall goal of Raghavan’s lab is to create novel materials that act as the basis for new technologies. Indeed, the hope in this particular research is that this robust technique – a method of inducing growth from the inside out – will be instrumental for creating other layered materials that may be useful in various areas, including tissue engineering.

This research was published in Nature Communications in August, 2017. For additional information:

Zarket, B. C., & Raghavan, S. R. (2017, August 4). Onion-like multilayered polymer capsules synthesized by a bioinspired inside-out technique. Nature Communications, 8(193). doi: 10.1038/s41467-017-00077-7

August 27, 2017

|