|

|

|

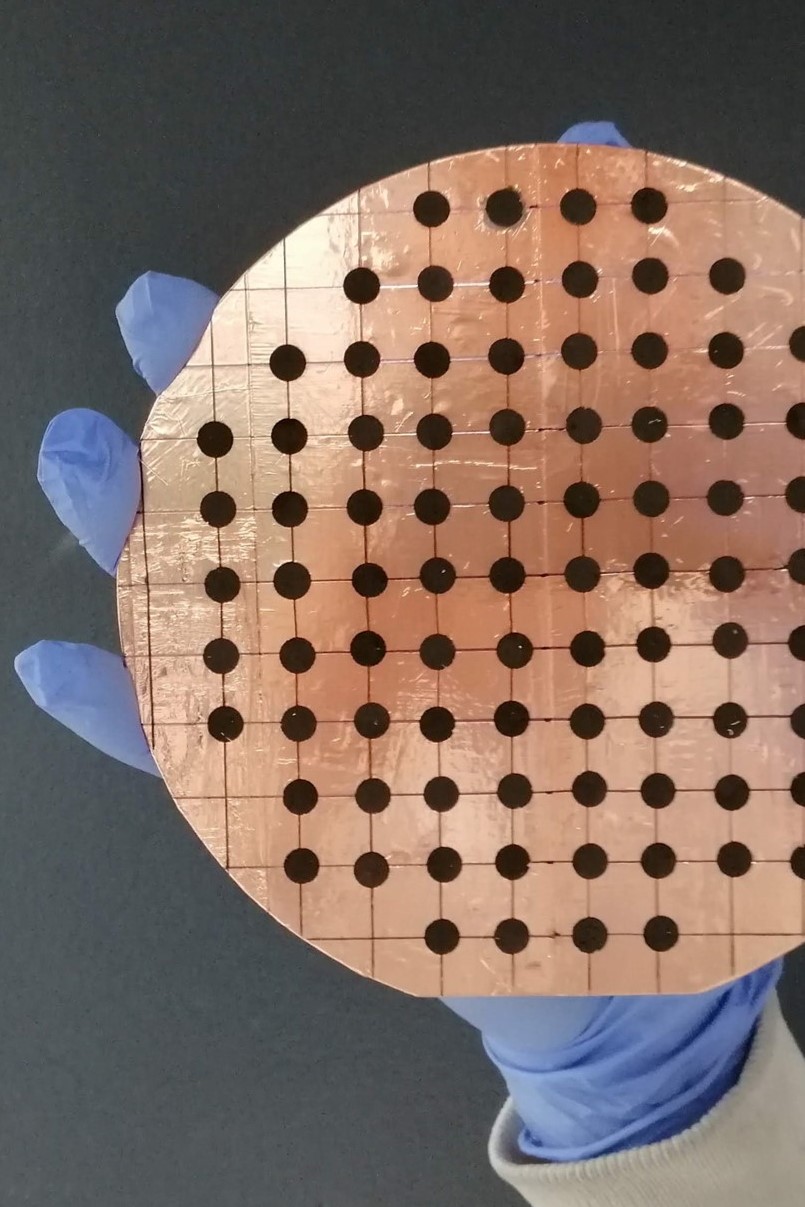

The nanoparticles located on this wafer are ready for testing for clean energy applications. |

|

COLLEGE PARK -- Researchers have developed a process that makes multi-material nanoparticles, which could be used in catalyzing reactions for fuel cells and clean energy reactions.

The process is high-throughput and combinatorial, allowing them to explore the characteristics of a range of elements, called the compositional space and including platinum, rhodium, palladium, rubidium, iridium, iron, cobalt and nickel, all near neighbors on the periodic table. The process is also rapid, designing and producing the nanoparticles within seconds.

The team that reported the results was led by Dr. Liangbing Hu, professor of materials science at the University of Maryland and Dr. Andre Taylor of New York University, and included collaborators from the University of Illinois at Chicago, Johns Hopkins University, California Institute of Technology, National Institute of Standards and Technology, and the Army Research Laboratory.

“This new technique can rapidly accelerate materials discovery toward high performance, low cost, and robust fuel cell catalysts,” said Dr. Yonggang Yao, first author of the paper, published March 10th, 2020 in Proceedings of the National Academy of Sciences.

A lay language version of this paper explains, “This demonstrated high-throughput material discovery pipeline presents a paradigm for facile and accelerated exploration of multielement materials, and are particularly intriguing as high performance and robust catalysts for clean energy applications.”

Theresearchers produced images of the new multimetallic nonclusters with the transmission electron microscope in the Advanced Imaging and Microscopy Lab (AIM Lab) of the Maryland NanoCenter.

High-throughput, combinatorial synthesis of multimetallic nanoclusters

Proceed. Nat. Acad. Sci. (2020)

https://doi.org/10.1073/pnas.1903721117

--end--

March 16, 2020

|