|

|

|

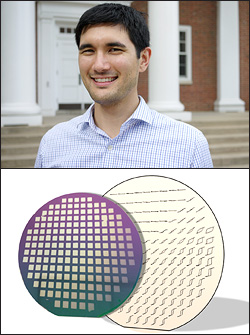

Above: Sean Fackler. Below: In a search for rare-earth free permanent magnets, Fackler and the Takeuchi Group fabricate combinatorial libraries in which iron, cobalt and vanadium compositions vary over a 3 inch silicon wafer. The actual combinatorial wafer is in front and behind it are the magnetic hysteresis loops superimposed over each sample position. One can easily find the areas of interesting magnetic properties based on the wide shape of the hysteresis loops. This combinatorial method allows rapid exploration of new materials making discovery and application in commercial markets faster. |

|

For millennia, magnetism has enabled revolutionary technologies like the compass, electric generators and motors, and hard drives and credit cards for digital media and commerce. Since the 1980s, neodymium and dysprosium have been used in alloys to create the most compact and powerful magnets, making our mobile media lifestyle possible.

Neodymium and dysprosium, known as rare earth elements, are part of a group of elements the U.S. government has classified as “critical materials”1 due to their importance to civilian and military applications and their failure to meet demands for supply. Despite the name, they are relatively abundant. However, 95% of the world’s supply is obtained from China, raising concerns about future availability and cost. Mining and refining rare earth elements also requires toxic chemicals, produces radioactive waste, and is detrimental to the environment. Unfortunately, no comparable materials exist, leaving thousands of products reliant on neodymium, dysprosium, and other rare earth elements.

At the University of Maryland, Department of Materials Science and Engineering (MSE) graduate student Sean Fackler is searching for alternatives to permanent magnets made with rare earth elements. His recent work, which demonstrates how to quickly and efficiently discover new magnets and reinvent less successful ones, received the 2014 Rare Earth Permanent Magnet workshop poster award, the 2014 NanoDay entrepreneurship award, and a Center for Nanophysics and Advanced Materials talk award.

Alloys of iron and cobalt are well known for their magnetic properties. Typically, in order to improve their strength and machinability, a third element is added. Vicalloy, the subject of Fackler’s study, is a permanent magnet made of iron, cobalt and vanadium. The material has been studied and used since the 1940s, but interest in it has waned in favor of magnets containing rare earth elements, which are up to 20 times stronger. Fackler’s experiments show that with some reworking, vicalloy’s properties can be enhanced.

Fackler, a member of MSE professor and Maryland NanoCenter member Ichiro Takeuchi’s research group, was able to assess vicalloy’s potential in minute detail using a technique that was unavailable to its creators in the 1940s and 1950s: combinatorial materials synthesis, also known as “combi.”

Combi allows Fackler and Takeuchi to quickly create and screen hundreds of unique materials samples of varying compositions to determine which, if any, have the properties they’re looking for. The process is like spray-painting a triangular panel with three different colors, each one starting out at a different corner. As the paints cross paths, they create a gradual change in color across the triangle’s surface, allowing the artist to quickly identify the mixtures that result in the most beautiful hues. In this case, iron, cobalt and vanadium were the spray paints, in the form of thin film deposits on a three-inch silicon wafer. It was in this “combinatorial library” of vicalloys that Fackler discovered one of them was a much stronger magnet.

Combi has been used previously to discover catalysts, fluorescent materials, shape memory alloys, and even superconductors, but Fackler’s study is one of the first to use it to search for new and improved permanent magnets.

“Using combi, we have a better chance of finding an optimal composition that has been overlooked with less systematic methods,” he explains. “We can also use it to systematically study the origin of a material’s magnetic properties. Understanding and controlling these attributes will help us improve vicalloy and other known permanent magnets.”

In the case of vicalloy, Fackler and his colleagues found that a particular columnar nanostructure seemed to be responsible for their best-performing sample, whose magnetic strength was four times greater than the original product. That isn’t enough to put it in contention to replace the best permanent magnets, but what the team learned in the process is a step in the right direction.

“Our finding suggests that we could use this nanostructure as a template to engineer other magnetic alloys that are about half as good as the best ones containing rare-earth elements.” Fackler says. “That would be a market changing accomplishment.”

Vanadium is only one of a group of transition metal elements (including tungsten, tantalum, and molybdenum) that the Takeuchi Group is mixing with iron and cobalt to create combinatorial materials libraries for further evaluation.

“The biggest challenge to finding alternatives to rare earth magnets is that it's like playing the lottery,” says Fackler. “Most discoveries of new materials are very fortuitous and often don’t rely on predictions or theory. They are simply stumbled upon from trial and error. The idea with the combi method is that we can win the lottery by holding all the tickets.”

1 For example, see: Department of Energy, “Critical Materials Strategy.” December 2010. Retrieved online 15 October 2014 from energy.gov/sites/prod/files/edg/news/documents/criticalmaterialsstrategy.pdf

Related Articles:

Discover, Create, Deploy: Professors Contribute to Materials Genome Initiative

$3.2M ARPA-E Award Supports Development of Combined Cooling/Heating/Power System

October 23, 2014

|