|

|

|

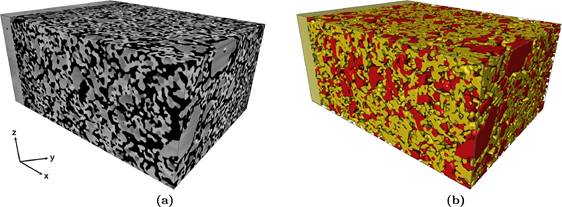

A 3D image cube on the left, and how it’s ‘segmented’ into different phases on the right. This segmentation process ‘labels’ every point within the dataset as cathode, electrolyte, or pore space, enabling specific quantifications. |

|

One of the biggest challenges in the materials engineering field is the variation in research methods, which for the most part, go undocumented in current literature – the results are generally all that is recorded; thus, it becomes difficult to compare results between two research groups, as it is unclear if differences originate from sample changes, or simply methodology. To that end, a group of researchers in the Department of Materials Science and Engineering at the University of Maryland – led by Lourdes Salamanca-Riba and Eric Wachsman, both MSE Professors – sought to improve the methods and techniques used when constructing a nanoscale 3D model of a given material - solid-oxide fuel cell (SOFC) cathode, in this case – with a FIB/SEM (Focused Ion Beam/Scanning Electron Microscope).

In Maryland’s AIMLab, the group performed a technique called ‘nanotomography,’ which is similar to a deli-slicer, but at the nanoscale. “Because the FIB/SEM can both modify materials and take very high-resolution images, we can use the FIB (a heavy beam of ions) to mill away a very thin layer of material (approximately 20nm), and after each ‘slice,’ we take an image with the SEM, leaving a stack of hundreds or thousands of images, which can then be combined using software to create a 3D representation of the sample,” said Josh Taillon, first author on the corresponding research paper. “These techniques can be used not just for SOFCs, but in a wide range of materials and geological fields, including 3D chemical analysis of advanced alloys, microstructural characterization of Li-ion battery electrodes, and pore structure characterization in shale gas samples."

At a very high level, an SOFC works to convert a chemical fuel (e.g. hydrogen or methane) into electrical energy. “This occurs through a series of reactions that combine fuel and oxygen ions at the anode to create free electrons that can be used as a power source,” Taillon explained. “On the cathode side electrons are combined with oxygen present in the air, to create the oxygen ion needed at the anode. In order for all this to work, the electrons and ions must be separated – the oxygen ion travels through the electrolyte material to the anode side of the cell, while the electron is conducted away for useful work – like powering a motor, for example.”

When images are converted to a 3D model, measurements can be taken – such as the surface area and volume of each phase, and the average porosity (impossible to obtain using 2D imaging) – offering a more specific explanation of how fuel cells perform.

More advanced quantifications can also be calculated, such as the tortuosity – the property of porous materials, such as soil or snow, to curve or twist – and most importantly, the triple-phase boundary (TPB).

“The TPB is all the places in the 3D structure where the three parts of the composite cathode (the electrolyte, which conducts ions; the cathode material, which conducts electrons; and the empty pore space, which conducts O2) come together – as the TPB increases, the reaction rate increases, and performance of the cell does, too,” Taillon explained. “In our research, we have presented improved ways to calculate both tortuosity and TPB statistics.”

To view a brief animation of one of the reconstructions, which shows the progression from 3D image data to quantifiable information about the microstructure, please follow this link:

https://www.youtube.com/watch?v=H_xQXeiliO4

For additional information on this research:

Taillon, J., Pellegrinelli, C., Huang, Y., Wachsman, E., Salamanca-Riba, L. “Improving microstructural quantification in FIB/SEM nanotomography.” Ultramicroscopy, January 2018. DOI: 10.1016/j.ultramic.2017.07.017

January 10, 2018

|