|

|

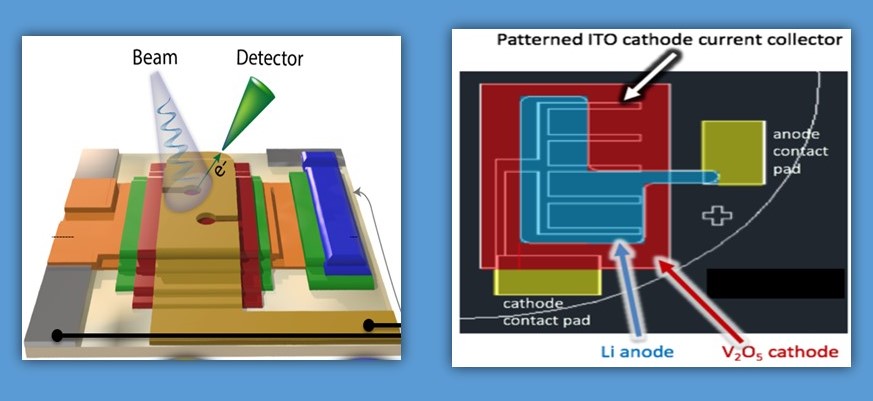

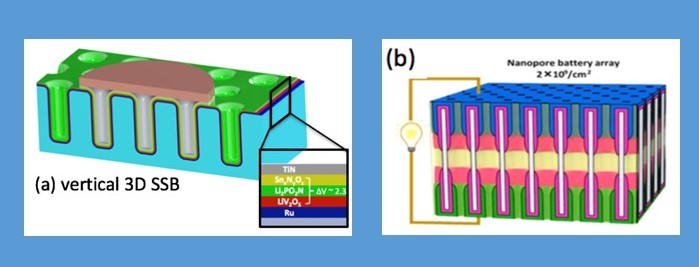

Instead of making battery layers on top of each other, arrranging them in 3 dimensions provides new measurement capabilities that promise unprecedented scientific insights for future battery technologies. |

|

Society is constantly on the look-out for safer, more efficient, and more cost effective rechargeable batteries. All-solid-state batteries (SSBs) are made with nonflammable, solid electrolytes – such as ceramics or polymers – which eliminate the risk of fire in mobile devices and electric automobiles, while offering high energy and power density and strong cycling ability.

To meet these demands, a University of Maryland (UMD) research team in the A. James Clark School of Engineering will conduct a 3-year investigation "Thin Film Platforms to Advance Scientific Frontiers in Solid State Energy Storage," supported by $2.25M in funding from the U.S. Department of Energy (DOE) Office of Basic Energy Science (BES) through its materials chemistry program. The research is aimed at illuminating fundamental science of electrochemistry at the nanoscale as it determines the power and energy performance of electrical energy storage devices.

Gary Rubloff, a distinguished university professor in the Department of Materials Science and Engineering (MSE), is the principal investigator on the project. Paul Albertus (ChBE Asst Professor and MEI2 Associate Director), Sang Bok Lee (Chem/Biochem Professor and NanoCenter Director) and A. Alec Talin (MSE Adjunct Professor and distinguished member of the technical staff at Sandia National Lab) will serve as co-investigators. The team focuses on precision 3D battery designs fabricated by the techniques that have driven the microelectronics and related industries for decades, an approach in stark contrast to today’s battery industry.

The research builds on the unique directions of Nanostructures for Electrical Energy Storage (NEES), an Energy Frontier Research Center (EFRC) sponsored by the DOE-BES from 2009 to 2020 and funded for $27.2M, with Rubloff and Lee as Director and Deputy Director. In the new DOE-BES program, researchers will exploit thin film fabrication techniques to create 3D structures capable of providing new measurements and insights currently inaccessible in conventional batteries. Some of these address what architectural shapes and dimensions are favorable not only for power and energy, but for stability during charge/discharge cycling. Others are aimed at determining properties of important interfaces buried underneath layers of battery materials and identifying how materials properties as ions when a battery is charging or discharging.

"Precision 3D battery architectures, controlled at the nanoscale, provide a profound opportunity to take battery science to a new level" said Rubloff. "We believe the resulting insights will benefit today’s technology and offer alternative pathways to how batteries are designed and manufactured."

"The grant underscores the commitment of DOE-BES to pursue the fundamental science underlying energy storage technology," said Lee. "This new DOE-BES program, and its ancestry in the NEES Energy Frontier Research Center, contribute profoundly to the strong leadership role that UMD plays in battery science and technology."

Related Articles:

Researchers’ Battery Breakthrough Improves Performance at Lower Costs

Maryland Engineers Get Cracking on Sustainability with Crab Shell-based Battery

Multi-institutional Research Team Documents Quantum Melting of Wigner Crystals

'Fluorinated interphase' bolsters water-based zinc battery chemistry

Building Energy Innovation in Maryland

Maryland Scientists Synthesize Metallic Glass Nanoparticles via High Temperature Thermal Shock

New government partner joins UMD’s Center for Research in Extreme Batteries

ARL to Fund $30M in Equipment Innovations for Service Members

University of Maryland leads team awarded $7.2M from Army Research Lab

UMD researcher receives new $1M Vehicle Technology Award

September 16, 2020

|