|

|

|

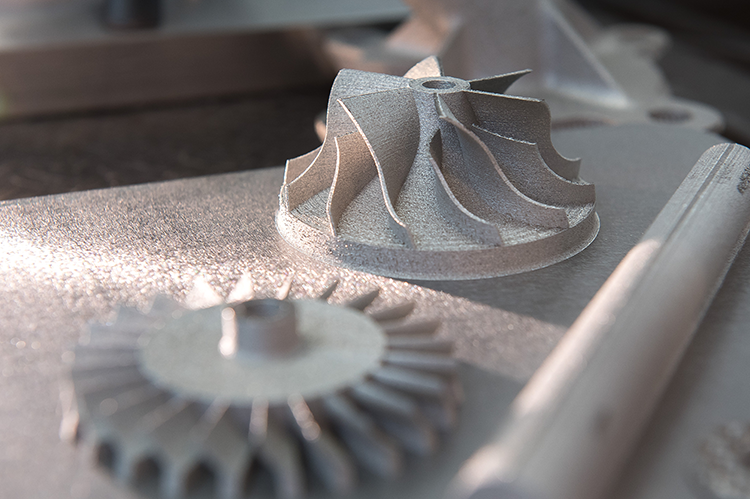

Using new technologies to create steel alloy parts from powder using a laser. Photo: David McNally, U.S. Army |

|

The University of Maryland and U.S. Army Research Laboratory (ARL) have announced a $22.8 million agreement to accelerate cutting-edge additive manufacturing materials and technology, aiming at helping the Army more efficiently and cost-effectively produce equipment with enhanced capabilities for service members.

It follows a $7.2 million research award from the ARL to develop advanced batteries for troops working in harsh conditions.

"Our goal is to build a science and technology ecosystem in the Washington, D.C. metropolitan area that will encourage groundbreaking advances in basic and applied research in additive manufacturing to achieve deep knowledge creation that will have long-lasting impacts on the U.S. national defense capabilities," said J.C. Zhao, chair of the Department of Materials Science and Engineering and principal investigator of the project on additive manufacturing, frequently called 3D printing.

This venture will stimulate experimental designs and prototyping, computational modeling and simulations, as well as establish a solid workforce development pipeline between academia and the Army.

The project funds work by researchers Ichiro Takeuchi, Eric Wachsman, and Zhao in Materials Science and Engineering; Hugh Bruck, Siddhartha Das, Abhijit Dasgupta, Mark Fuge, Patrick McCluskey, Michael Ohadi, Ryan Sochol, and Don DeVoe in Mechanical Engineering; Norman Wereley in Aerospace Engineering; Peter Kofinas in Chemical and Biomolecular Engineering; John Fourkas and Sang Bok Lee in Chemistry and Biochemistry; and Richard Marciano in the College of Information Studies.

"This collaboration will establish the critical foundational knowledge base to enable next-generation materials discovery and new products," said Jian Yu, Army researcher and cooperative agreement manager for the U.S. Army Combat Capabilities Development Command’s ARL.

In the second project, UMD will lead a collaboration with academic, industry, and federal partners to develop batteries for troops using them in extreme working environments, including batteries that charge faster, reduce flammability risk, have a higher energy density and lower mass, and function in very hot and cold temperatures.

Wachsman, director of the Maryland Energy Innovation Institute and William L. Crentz Centennial Chair in Energy Research of Materials Science and Engineering, and Chunsheng Wang, director of the Center for Research in Extreme Batteries Consortium (CREB) and Wright Distinguished Chair of Chemical and Biomolecular Engineering, will oversee the effort.

"The Army is rapidly increasing its usage of batteries for diverse applications, including portable soldiers’ systems, unmanned vehicles, hybridized next-generation combat vehicles, directed energy systems, and more," said Wesley Henderson, the ARL lead for CREB.

Additional partners in the program include Montana State University, Stony Brook University, and the University of Texas-Austin; corporate partners Saft America, Ion Storage Systems, New York Battery & Energy Storage Consortium, and Graphenix Development; and national laboratories Argonne National Laboratory, Brookhaven National Laboratory, and the National Institute of Standards and Technology.

Related Articles:

Researchers’ Battery Breakthrough Improves Performance at Lower Costs

UMD Scientists Achieve Ultrahigh-Temperature Melt Printing

Maryland Engineers Get Cracking on Sustainability with Crab Shell-based Battery

Building Energy Innovation in Maryland

Mighty Morphing 3D Printing

New government partner joins UMD’s Center for Research in Extreme Batteries

University of Maryland leads team awarded $7.2M from Army Research Lab

UMD Research Team Advances the Battery Revolution

UMD researcher receives new $1M Vehicle Technology Award

Sulfur Provides Promising 'Next-Gen' Battery Alternative

October 23, 2020

|